To house my book, my friend Cathy suggested a slipcase construction that was invented by Denise Carbonne. Here’s briefly how to make one.

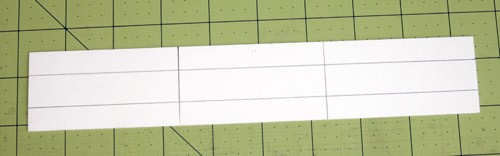

Start with 3 pieces of paper. One piece is folded to form the slipcase top, spine and bottom. Two other pieces make the sides of the case. The spine piece length is (2 * the width of the book) + the length of the book. The width of the spine piece is the width of book + 1 inch. The side pieces are (2 times the book width) by the book height. These numbers will need to be adjusted a bit depending on the thickness of the material used to make the slipcase.

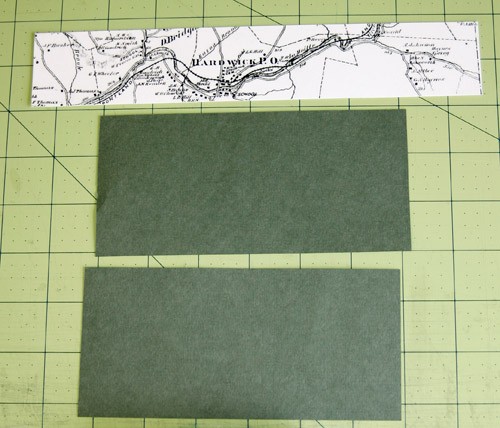

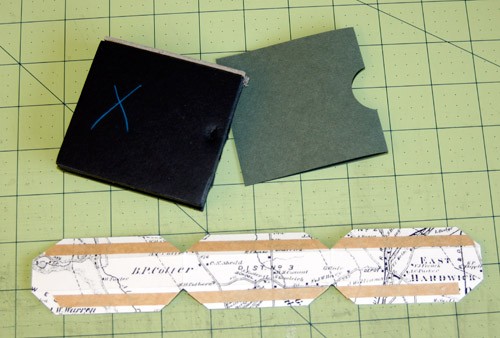

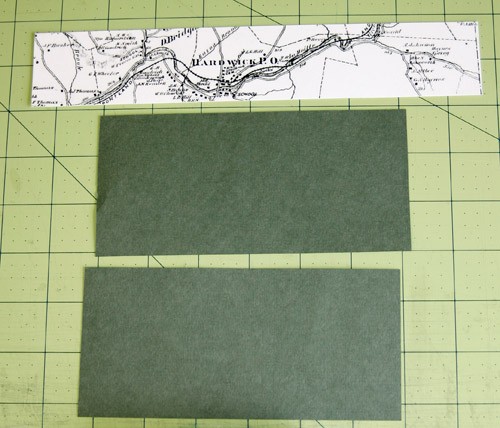

My book is 3″x3″x.5″. The spine piece (top of photo above) is 9.25″x1.625″. The 2 lower pieces of paper are 6″x3″. (Because of the paper I’m using, and to allow the book to go in and out of the case easily, I needed to add 1/8″ to dimension of the book — width, height, and length.)

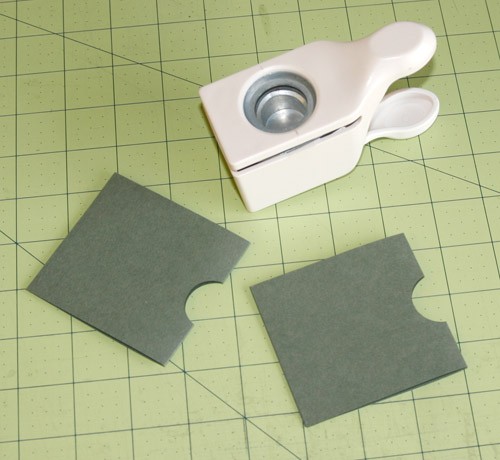

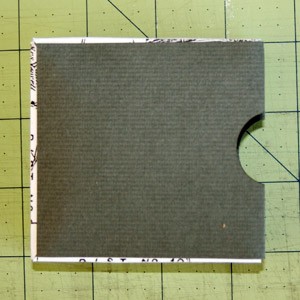

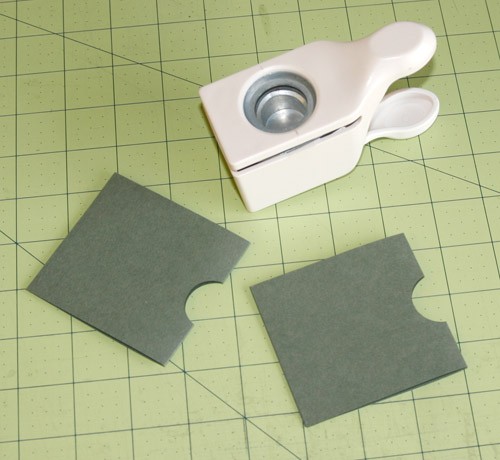

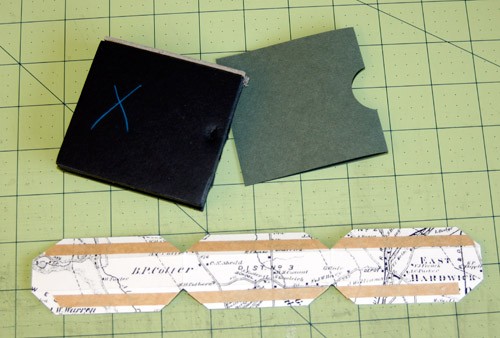

Next I folded the side pieces in half and used a 1″ round hole punch to make half holes in the folded edge of the paper. This will make it much easier to grasp the spine of the book and remove it from the slipcase.

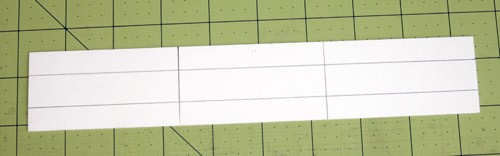

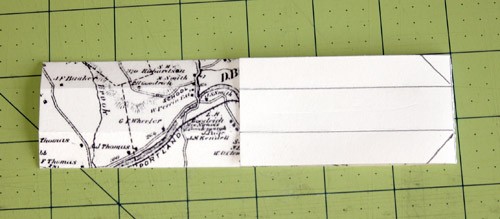

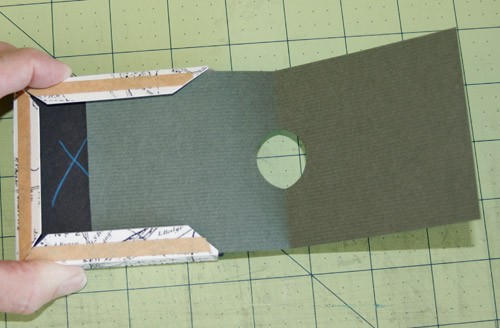

Prepare the spine piece by scoring 1/2″ from either long edge. Then score the width of the book from either end (in my case, this is 3-1/8″ from either end). I’ve drawing the score lines on the opposite side of the spine piece in the photo below.

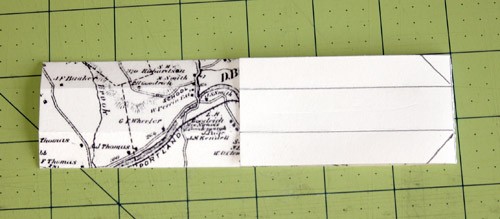

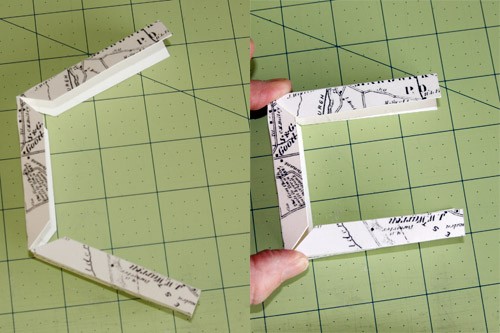

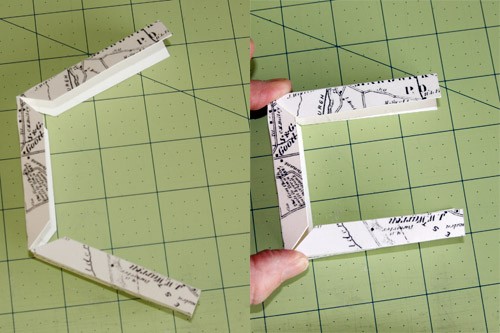

Fold along the scores and then fold one end over and miter each edge — see photo below.

The miters allow the paper to fold to form the spine, top and bottom of the slipcase

Using several pieces of foam core, I made a block that is the same size as my book. This makes it easier to attach the side pieces to the spine. Instead of using glue, I used 3M 415 double-sided tape. It’s got a backing on one side, so I could get everything positioned and then adhere it, without worrying about glue drying or getting all over everything. The tape goes along the 2 horizontal scores on both sides (front and back) of the spine piece. Here’s a picture of the spine piece, my foam core block and one of the side pieces.

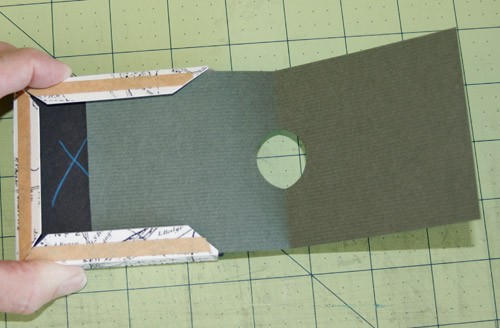

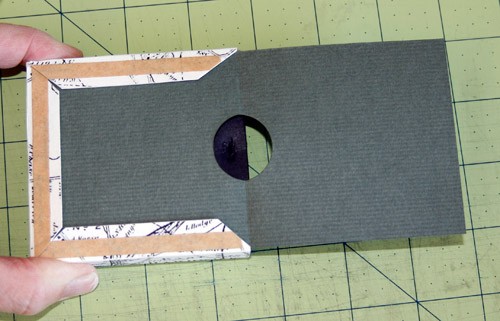

In the next photo, I’ve positioned the foam core block inside the folded spine piece. Then I slipped in the open side piece of paper. I haven’t removed the backing on the tape yet.

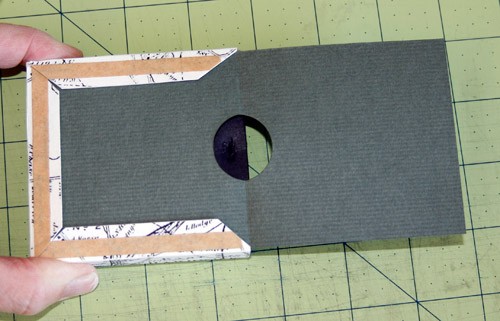

Once I’ve got everything positioned, I remove the tape backing and press down the spine piece so the mitered edges meet. In the photo below, I’ve removed the backing between the spine piece and the side piece and boned them down. This step is a bit tricky, as the spine piece has a tendency to creep out at the far edge (where the book would be inserted), so I had to be mindful that I kept everything tight as I adhered them.

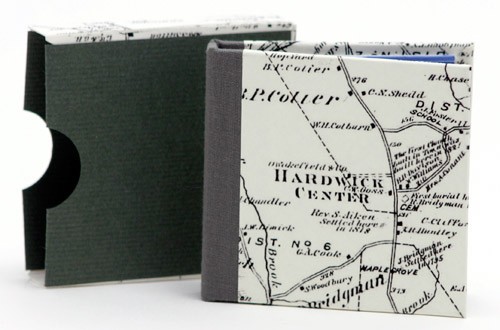

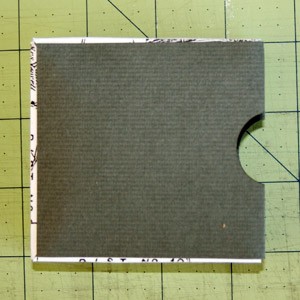

Now I remove the backing on the tape on the top, fold over the side piece and adhere it. That finishes the first side. Turn over the slip case and adhere the second side piece, remove the foam core block, slip in a finished book, and I’m done.

Now I remove the backing on the tape on the top, fold over the side piece and adhere it. That finishes the first side. Turn over the slip case and adhere the second side piece, remove the foam core block, slip in a finished book, and I’m done.

I used 80 lb cover stock for the spine piece, printed with the same map as on the cover of my book. For the side pieces, I used Bugra paper (which is the same color as the book cloth I used for the book’s spine).

Now I remove the backing on the tape on the top, fold over the side piece and adhere it. That finishes the first side. Turn over the slip case and adhere the second side piece, remove the foam core block, slip in a finished book, and I’m done.

Now I remove the backing on the tape on the top, fold over the side piece and adhere it. That finishes the first side. Turn over the slip case and adhere the second side piece, remove the foam core block, slip in a finished book, and I’m done.

I’m in the middle of hand-setting the haiku for my current book production. I’m printing the pages 2-up. There’s 7 haiku, the title page and the colophon (that’s the title page and colophon all laid out in the photo to the left). Not really very much type, but it’s required a lot of concentration. I get one chance to get the spelling right, and notice if, for instance, I used the wrong space width between words. When I print text from photopolymer, which I set on the computer in InDesign or Illustrator, it seems I have a lot more time to check myself before getting the plates made — not to mention the spell checker!

I’m in the middle of hand-setting the haiku for my current book production. I’m printing the pages 2-up. There’s 7 haiku, the title page and the colophon (that’s the title page and colophon all laid out in the photo to the left). Not really very much type, but it’s required a lot of concentration. I get one chance to get the spelling right, and notice if, for instance, I used the wrong space width between words. When I print text from photopolymer, which I set on the computer in InDesign or Illustrator, it seems I have a lot more time to check myself before getting the plates made — not to mention the spell checker!