Removing the magnet top from my magnetic base

|

When I started letterpress printing, the only way to print with photopolymer was to make steel-backed plates and then use a magnetic base to mount the plate in the press. Over time I’ve acquired 4 bases in various sizes. One nagging problem with these bases is that the magnet is weak to begin with and degrades over time so that the plates don’t stay put. I resort to tape and spray adhesive to keep the plates in register. |

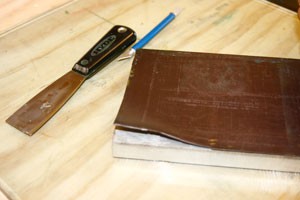

![]() I used a xacto knife and metal ink spatula to take off the magnet top, and cleaned off the underlying adhesive with goof-off. Then using the sheet adhesive I got from John, I applied the gridded mat.

I used a xacto knife and metal ink spatula to take off the magnet top, and cleaned off the underlying adhesive with goof-off. Then using the sheet adhesive I got from John, I applied the gridded mat.

![]() Some final gory technical details: One mat won’t make the base high enough and John suggested red pressboard (available from NA Graphics) but I didn’t have enough, so I adhered a second mat to the bottom of the base. It helps to have a measuring caliper to get the right height. A Boxcar aluminum base is .854″ high, my magnet converted base was .860″ before and after conversion.

Some final gory technical details: One mat won’t make the base high enough and John suggested red pressboard (available from NA Graphics) but I didn’t have enough, so I adhered a second mat to the bottom of the base. It helps to have a measuring caliper to get the right height. A Boxcar aluminum base is .854″ high, my magnet converted base was .860″ before and after conversion.